SMITH Gaskets supplies a comprehensive range of oilfield products and services including industrial gaskets, advanced cutting services and hi-tech testing facilities.

A gasket is an elastomeric component that covers the point where two surfaces meet. They are often made of a range of materials, such as rubber, cork or paper, metal, copper, and foam. Because of its versatility, this adaptable element may be utilized for a variety of applications. These include anti-vibration, packaging, cleanliness, noise and sound reduction, and, perhaps most significantly, sealing. Gaskets are utilized in almost every industry, including food processing, petrochemicals, pharmaceuticals, water, and gas. Gasket materials are selected for their properties and capacity to endure a variety of conditions, including mining and deep-sea environments, as well as resistance to chemicals, alkaline acids, high temperatures, and pressure

How does a Gasket work?

A gasket must be squeezed enough to create a complete barrier that will form a pressure-tight seal and protect the contents within the seal in order for it to operate properly and seal away any leaks. Furthermore, gaskets protect moving components of an application by preventing them from rubbing against hard surfaces and causing friction. An elastomeric gasket is a component that creates a seal between two surfaces by sealing against the release or intake of both gases and liquids. They are excellent for filling defects and connecting two surfaces. Because a gasket will cover the gap between these two surfaces, it must be made of a material that is readily deformed and fills any imperfections. Compounds such as spiral wrapped gaskets are often made from a combination of metallic and softer filler material (flexible graphite). Metal gaskets must most of the time be squeezed at a greater tension in order to seal accurately. In certain instances, a sealant must be placed directly to the gasket to provide a leak-free seal.

Applications for Gaskets

A gasket is an important component in various production processes since they are available in a variety of specifications. Gasket material is selected for an installation based on properties like as resistance to chemicals, temperatures (or temperature variations), pressures, acids, gases, and, in certain cases, electromagnetic or electrical forces. Gaskets are widely used and may be found in automobiles, trains, aircraft, boats, electrical equipment, pumps, and a variety of other uses.

Industries that make use of gasket

A gasket material has the ability to withstand some of the most demanding conditions for industrial sealing goods, such as:

- Chemical synthesis

- Production of electricity

- Petrochemical and deep-sea exploration

- Oil and gas

- Mining

- Military

- Aerospace

- Filtration

- Food and Beverage

- Pharmaceutical

- Industries involved in sanitary processing

Gaskets may be manufactured using a variety of methods, depending on the material and application, including:

- Extrusion of rubber

- Cold bond splicing and hot vulcanized splicing

- Compression molding, injection molding, and transfer molding

- Slitting with precision

- Personalized die cutting

- Waterjet chopp

Gaskets and seals are used in almost every application and sector, including oil and gas, manufacturing and industrial uses, pulp and paper production, and agricultural equipment. Gaskets that have become worn or damaged are simple to repair. It is common practice to replace gaskets whenever the equipment is dismantled and rebuilt.

PRODUCT OF SMITH Gaskets

RING TYPE JOINTS

Ring joint gaskets are metallic sealing rings suitable for high pressure and high temperature applications and are fitted in ring groove type flanges.They are widely used in the Oil/Gas and Petrochemical industry, in valves and pipe-work. Choice of material may be determined to suit higher temperatures and aggressive media. They comply with ASME B16.20 standards and API spec 6A (where applicable).

The gasket hardness is carefully controlled and shall always be softer than the mating flanges to ensure a good seal and no damage to the flange surface (note: RTJ gaskets should not be re-used). All SMITH RTJ gaskets are manufactured from fully traceable materials and are stamped to the requirements of API 6A and ASME B16.20. DIN 50049 3.1 certification is supplied with all orders. The gaskets are machined to the required tolerances and surface finish using high quality CNC lathes. All soft iron and carbon steel RTJ gaskets are electroplated with zinc 0.0005″ thick in accordance with API specifications. Other non-standard styles of metal rings are also available like combination, IX, Delta and Lens to customer specifications.

1) TYPE R

R type ring joint gaskets are available in oval or octagonal cross section and manufactured in accordance to API 6A and ASME B16.20 to suit API 6B and ASME/ANSI B16.5 flanges. The oval ring fits the round and flat bottom ring groove flange, while the octagonal shape fits only the modern flat bottom groove flange.

2) TYPE RX

The RX type RTJ gasket is manufactured in accordance to API 6A and ASME B16.20 to suit API 6B and ASME/ANSI B16.5 flanges. The RX is a pressure energized version of the R octagonal gasket and fits the R type flat bottomed groove.

The RX has an increased height and utilizes the internal system pressure to energize and improve the seal as internal pressure increases. Some RX sizes have a pressure relief hole to equalize pressure both sides of the sealing faces

3) TYPE BX

The BX type RTJ gaskets are manufactured in accordance with API 6A and are suitable for use in high pressure API 6BX flanges.The gaskets form a metal-to-metal seal on assembly and the efficiency improves as internal pressure increases. All BX sizes have a pressure relief hole to equalize pressure across sealing faces.

- SRX and SBX RTJ gaskets to API 17D for subsea applications.

- IX rings for compact flanges

- Other non-standard styles of metal rings are also available like combination, IX, Delta and Lens to customer specifications

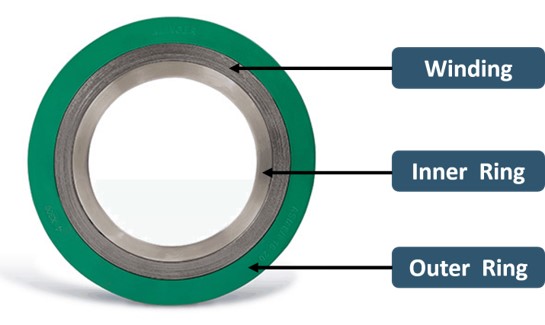

SPIRAL WOUND GASKETS

Spiral Wound Gaskets are suitable for a wide range of operating conditions and can be adapted to suit almost all applications. The gaskets can seal fluid pressures up to 250 bar and temperature range of -200°C to in excess of 450°C.

THICKNESS : All RS and RSI gaskets for standard flanges have a 4.5mm thick sealing section of windings and filler material, with 3.2mm thick solid metal guide rings.

https://www.gmsthailand.com/product/smith-gaskets-smith-international-gulf-services/